%20(1).png?width=555&name=Untitled%20design%20(3)%20(1).png)

Sugarcane is a great renewable source that can be used to create 100% recyclable plastic. As sugarcane plastic is molecularly identical to standard oil-based plastic, it is a great sustainable solution that doesn’t mean compromising on product quality. One of the significant advantages of sugarcane plastic is that the process of growing its raw material (sugar cane), removes carbon dioxide from the atmosphere, which results in significant gains for the environment.

In fact, in the 6 years since moving to sugar plastic Ecostore saved 7,676 tonnes of carbon from being released into the atmosphere. This is the same as driving a car from Cape Reinga to Bluff 14,610 times.

Created by scientists at the Centre for Sustainable Chemical Technologies (CSCT) at the University of Bath, sugar plastics do not require excessive temperatures or pressures to be created. As a result, it’s not only their raw material that is more appealing than traditionally-produced plastics, but also their production method that offers a sustainable alternative.

Yet despite its quick adoption as an alternative packaging material, there are several myths about sugar plastics that continue to circulate. As one of the latest suppliers of sugar plastic products in New Zealand, we thought we’d tackle several of these myths and explain which are true, and which are false.

Myth 1 - Sugar cane plastic cannot be recycled

False! In fact, unlike biodegradable or compostable plastics, sugar plastic can go through the recycling infrastructure we already have. They are collected, processed, and repurposed in the same way as oil-based plastics. Because sugar plastic is chemically and compositionally identical to everyday plastics, it can be integrated into your kerbside collection.

Myth 2 - Sugar cane plastic biodegrades

False! Sugarcane plastics are neither compostable nor biodegradable, but this isn’t necessarily a bad thing. Sugarcane plastics can be processed by a normal recycling facility, unlike biodegradable plastic. If sugar plastics could biodegrade (or were incinerated), that would release the captured carbon dioxide within the sugar, releasing it into the environment. Recycling it like normal keeps the carbon captured and keeps the sugarcane plastic being reused.

Even if something is labeled as biodegradable it may not biodegrade at all. That’s because biodegradability is highly dependent on environmental factors. For a material to biodegrade it needs the right conditions of heat, light, and moisture for organisms and bacteria to eat away at the material leaving no trace. Many biodegradable materials sent to landfills are not subjected to the conditions required to degrade quickly and efficiently.

Myth 3 - Sugar cane plastic is not a bioplastic

False! For a plastic to be defined as a bioplastic, it either needs to be bio-based (derived from biomass), biodegradable, or a combination of the two. So while we’ve already highlighted that sugar plastic is not biodegradable it is derived from biomass – sugar cane.

It’s important to note that not all biodegradable plastic will fully break down. Some, particularly oxo-degradable plastics, are conventional plastic with an additive that breaks the material down. But rather than fully degrade they create tiny fragments of the original plastic, often imperceptible to the human eye. These microplastics are more harmful to the environment than their whole status as these smaller particles are ingested by animals and find their way into the food chain. In fact, oxo-degradable plastic has been included in the government problem plastic phase out program, due to its negative environmental impact.

Myth 4 - Sugar cane plastic results in land clearing

False! Using sugar cane as a raw material is another way that we can protect our forests. 5 tons of wood are needed to produce 1 ton of pulp for paper, while only 1.5 tons of sugar cane pulp is required to produce the same amount of paper.

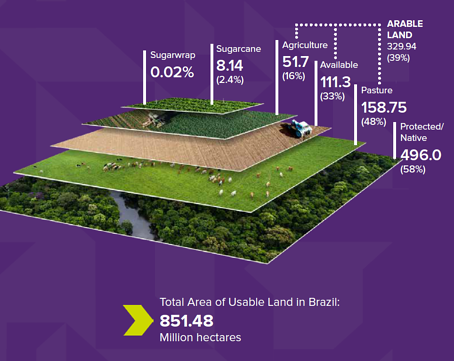

Sugar cane can also be grown on land that can't be used for anything else. Growing sugar cane on unusable land in Brazil for example actually replenishes the soil. Plus, sugarcane plastic only uses 0.02% of Brazil’s land.

Myth 5 - Sugarcane plastic is lower in quality in comparison with petrol-based plastic

False! Sugarcane plastics have an identical chemical composition as petrochemical plastics and can even be mixed in with ‘normal’ plastic to form recycled plastics.

Myth 6 - Sugar cane removes CO2 from the atmosphere

True! Sugar cane captures CO2 from the environment as it grows. According to some sources, every kilogram of sugar cane plastic produced removes 3.09 kg of CO2 being removed from the air.

While most carbon capturing materials (such as wood) release this carbon when burned, sugar plastics are recycled, meaning the carbon they’ve captured is not released back into the atmosphere. Sugar cane is harvested every year enabling a new crop to capture carbon and store it. The more sugar cane produced the more carbon is taken from the atmosphere and stored.

Myth 7 - Sugar cane plastic isn’t sustainable.

False! As we’ve already alluded to, sugar cane is fast becoming a sustainable solution to less environmentally friendly packaging materials like oil-based plastic. Sugar cane is considered a renewable resource that’s sustainable – unlike paper which is generally harvested from virgin forests, which are quickly becoming endangered.

The process of turning sugar cane into an environmentally friendly plastic is complex and involves the initial crushing of the sugar cane stalks to release the sugar juices. The next crushing phase breaks down the sugar even further; this is then used to create bio-ethanol – a plant-based alcohol. This bio-ethanol can be used as a petrol substitute, or to make plastic that is molecularly identical to traditional plastic made from fossil fuels. Manufacturers of sugar plastics use this ethanol as a biofuel for the production facilities manufacturing this new sustainable plastic, thus reducing their dependency on fossil fuels to run these facilities.

Myth 8 - Sugar cane plastic is as bad for the environment as normal plastics.

False! There are several areas in which sugar plastics offer significant environmental benefits versus petrochemical plastics. These include:

- The carbon capture of the raw material (sugar)

- The use of ethanol byproduct to power processing facilities

- Reduced energy consumption in processing

- No carbon dioxide output during production

- End-of-life suitability with current infrastructure and processes

- Reusability and recycling opportunity

- Reduced presence in landfill

While sugar plastic is not a 100% zero impact solution it is a significant improvement on current petrochemical options and its impact can be more easily regulated, controlled, and offset than petroleum-based options.

As a sustainable and more futureproof alternative, it is our best option yet to traditional plastics. Its impact on the environment, throughout its life, is significantly reduced and sugar plastic has even been highlighted as having a closer biochemical link to naturally occurring materials in our DNA. This means that unlike materials such as BPA, our use of the material in plastics containing ingestible materials (such as water bottles) is much safer.

As one of New Zealand’s leading packaging suppliers to businesses, we’re excited to see a viable alternative to plastic with no reduced performance and quality. We are championing sustainable alternatives as part of our environmental policy and stewardship on plastic production and distribution.

To learn more about the many ways in which we’re looking to improve our environmental impact, read more by clicking the button below.

.png)