Pallet wrap provides strength, protection and security for shipped goods. This perception is key when you begin to assess how it is used. After all, you'd think that using more pallet wrap on each shipment would mean more strength, more protection and more security. So it might surprise you that many businesses are actually wasting tens of thousands of dollars a year in waste from over-wrapping shipments.

A surprising reason for over-use of pallet wrap, and the estimated $60 billion of wasted goods from ineffective pallet wrapping is a mis-understanding of containment force.

What is containment force?

Containment force is the pressure the pallet wrap subjects the contained objects to. It's what holds the items within together and stops them shifting during loading and transportation.

Why does it matter?

If you apply too much containment force you're not only wasting pallet wrap and costing the business money, but you may be applying too much containment force to the goods within. When there is too much containment force, the goods within may become damaged due to excessive pressure being applied. There will also be more wasted wrap on the delivery end for your supplier or processing facility to deal with.

On the other hand, if you do not apply enough containment force then the goods within run the risk of becoming unstable and falling out. This can result in lost stock/goods and ancillary damage to transporters or people. There may also be additional cost of clean up.

So with costs associated for applying too much, and costs for not using enough what are your available options?

How much could the right pallet wrap save?

Disregarding the costs of lost stock through over-wrapping or under-wrapping, the cost of the wrap itself quickly makes a dent in any large-scale business. So how do you know how much pallet wrap you should actually be using for your specific shipment types?

One major food distribution business managed to save 75% on their pallet wrapping after a comprehensive, professional assessment showed they were over-wrapping their goods before transport. The reduction in the use of pallet wrap did not compromise the strength, security or protection of the goods and instead hit a sweet spot of operation.

75% saved through a professional pallet wrap assessment

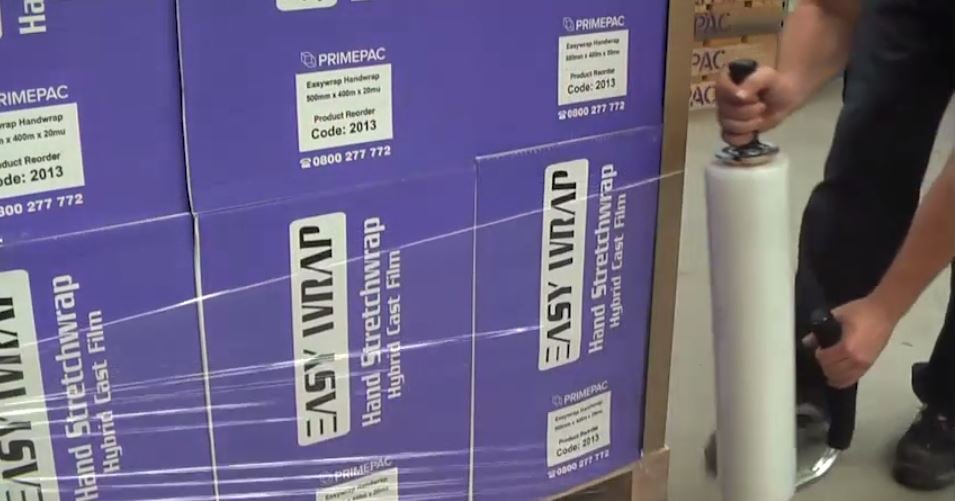

Part of the reason this was possible was because of the multi-layer technology used in Primepac's Ultiwrap. Ultiwrap comes as Ultiwrap machine wrap or Ultiwrap hand wrap and the application of layers make it possible to stretch the wrap further, without reducing the strength or puncture resistance of the wrap. And whereas optimal performance can be achieved with a pre-stretch machine head wrapper it's also possible to achieve great results from hand-wrapping.

Click here to see how much you could save by switching to Ultiwrap.

What's the solution to inefficient pallet wrapping?

Luckily, Primepac has a team of pallet wrap specialists that can conduct a free wrap efficiency consultation of your pallet wrap needs. They can tell you if you're using too much, or risking goods by not using enough. They can also make expert recommendations on viable solutions that could save your business money, and lower risk.

You don't even have to be an existing Primepac customer to take advantage of this service!

.png)