If you regularly transport fresh produce you’ll know the importance of making sure it arrives at it’s destination in the same condition as when it left. Often external factors can get in the way and keeping produce fresh can be difficult if your shipment is collected late, or the delivery schedule is running behind.

Traditional plastic wrap can present problems for fresh produce that's wrapped when warm, or cool. Produce such as bread for example, and chilled fresh produce and fish can develop moisture through condensation as they’re moved into warmer or cooler environments. When wrapped in normal wrap plastics this can result in a build-up of condensation as warm goods ‘sweat’. Therefore a breathable, yet strong, wrap is needed to deliver the best of both worlds.

We’ve been working hard to develop a new type of ventilated pallet wrap that will help to reduce damage to fresh produce during transit, while also enabling the contents to breathe. We’ve found the perfect solution – Ventiwrap. Find out more about best practices for shipping fresh produce and the benefits Ventiwrap can bring below.

Transporting fresh produce safely

Generally, all types of food products will experience some level of deterioration over time – this is particularly so for fresh produce. Due to the condition that fresh produce needs to be kept under to remain ‘fresh’, this type of food can be a lot harder to keep cool. Using the right packaging methods to keep fresh produce in top condition during transit will not only mean it arrives at its destination in one piece, but free from degradation and spoilage.

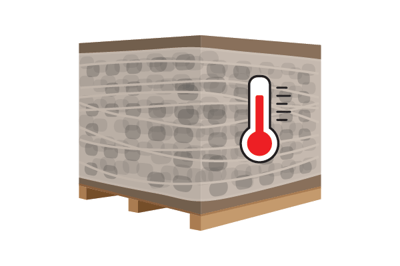

Temperature control can have a big impact on the quality of fresh produce and the condition the produce stays in during transit. Not only will the right regulated temperature keep produce looking good, it will also stop unwanted external factors like humidity and mould from taking hold. If produce is affected by humidity in particular, there’s the potential for whole pallet(s) of fresh produce going to waste, costing you time and money.

When transporting fresh produce like fruit and vegetables, it’s recommended that the shipments remain cold, at a temperature of 5 degrees or lower. You can help to regulate the temperature of your fresh produce with a ventilated wrap like Ventiwrap.

Ventilated pallet wrap – Ventiwrap.

Ventilated pallet wrap – Ventiwrap.

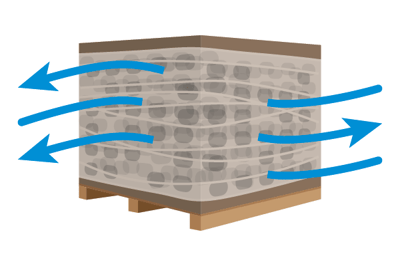

By using Ventiwrap in chilled transport you’re allowing the refrigerated conditions of the truck to control the temperature of the fresh produce directly. With a sealed pallet wrap the cool air of the transporter struggles against the warm air within the pallet wrap, resulting in the refrigeration only really chilling the outside of the plastic packaging wrap, rather than the goods inside. By using Ventiwrap you open up the pallet wrap to enable the cold air to permeate and chill the goods within.

With warm goods, like freshly baked bread, the Ventiwrap enables the still cooling bread to vent the warm air without it condensing on the inside of the plastic – it’s for this reason that many people transporting baked goods have steered away from pallet wraps for many years. This has resulted in using trays that interlock so the goods don’t move while enabling the produce to breathe. Now businesses transporting baked goods can add ventilated pallet wrap to the trays to increase security and strength during transport. With the ventilated pallet wrap providing additional rigidity, moving the goods on forklifts and loaders becomes extra safe.

What is Ventiwrap?

Ventiwrap is a new type of stretch film that has been developed specifically for the agriculture and horticulture industry, and wrapping pallets of fresh produce. We understand that fresh produce can spoil easily so we wanted to develop something that would help to prolong the life of fresh produce, particularly when being transported long distances.

Ventiwrap uses multi-layer film technology to achieve this and keep fresh produce at it’s best while in transit.

Ventiwrap benefits

There are quite a few benefits to using Ventiwrap for bundling fresh produce which include a reduction in damage to your produce. We’ve covered the main benefits below.

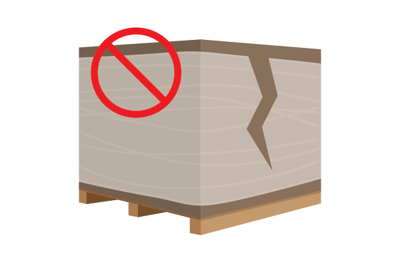

Reduces damage to fresh produce

Ventilated wrap is an ideal packaging solution for shipments of fresh produce, which are prone to spoiling due to ripening gases, humidity and mould. Ventiwrap helps to prolong the shelf life of fresh produce by giving it the circulation it needs during storage and transit. Air can easily circulate around the fresh produce to reduce humidity and evidential mould from being too warm.

Prevent damaged hot loads

Wrapping pallets of hot fill products with ventilated film allows condensation to be released as it cools, preventing damaging rust. Ventiwrap also has little to no insulation, meaning the cooling process is much faster than with conventional wrap.

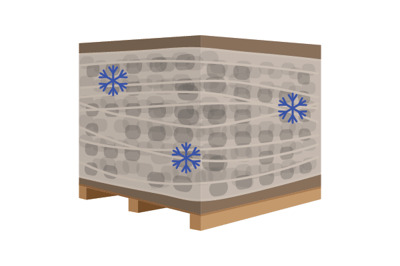

Reduce freeze downtime

Ventiwrap is perfect for loads that need to cool rapidly, as the increased airflow means there is very little insulation compared to conventional wrap. Pallets wrapped in Ventiwrap will greatly reduce electricity costs, because less energy is needed to reach the products target temperature.

Eliminate film breakages

Ventiwrap has reinforcement strips integrated into the film, giving it the strength of a conventional wrap, while retaining the lightness and breathability of a ventilated wrap. You can reduce downtime from breakages which will help to create a fast, efficient warehouse.

Use Ventiwrap to package your fresh produce

With multi-layer film technology, Ventiwrap is an effective pallet wrap to help air circulate around your fresh produce during transit, regulating temperatures and reducing the effect sometimes harsh shipping conditions can have on produce. Wrap it around your fresh produce and it will not only keep your items bundled together effectively, but it will also keep them in a lot better condition than traditional pallet wraps would.

Available exclusively as a Primepac product, you can purchase Ventiwrap online on our website.

.png)