Shrink wrap and pallet wrap are both common packaging materials used in a variety of industries. These two products are often used interchangeably, however, they’re not the same thing.

In this blog, we take a closer look at the two materials, comparing their properties, uses, and benefits. Whether you need packaging solutions for a small business or a full-scale warehouse, this guide will clarify the difference between shrink wrap and pallet wrap and help you determine which one is right for you.

What is shrink wrap?

Shrink wrap is a thin plastic film made of polyethylene that is used to wrap and secure individual items. When heat is applied to the wrap, it shrinks, forming a tight and secure fit around the item being packaged. This creates a barrier that protects the item from dust, moisture, and other environmental elements during shipping and storage.

.png?width=200&height=187&name=Untitled%20design%20(4).png)

Pros of using shrink wrap:

- Provides a protective barrier against dust and moisture.

- Suitable for small to medium-sized products.

- Cost-effective.

- Easy to use.

Cons of using shrink wrap:

- Some people are sensitive to the fumes produced when shrink wrap is heated.

- Can be a fire hazard if not used properly.

- Not suitable for heavy or fragile items.

When to use shrink wrap

If you are looking for a plastic wrap to package your products for display on store shelves, the glossy sheen and transparent appearance of shrink film make it a suitable choice. Due to the effective layer of protection, it provides, shrink wrap is ideal for packaging small products like books, food, electronics, appliances, tools, homewares, toys, and medical supplies.

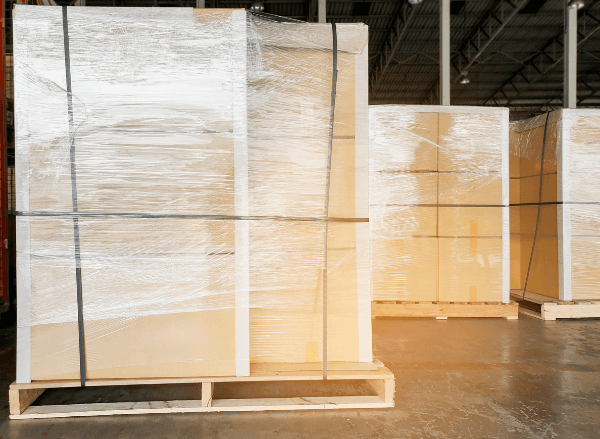

What is pallet wrap?

Pallet wrap, also known as stretch wrap, is a thin plastic film that is used to wrap and secure groups of items on a pallet for shipping and storage. Unlike shrink wrap, pallet wrap is stretchable and is designed to tightly secure items together on a pallet to prevent them from shifting during transportation.

Pros of using pallet wrap:

- Keeps items securely in place on a pallet.

- Cost-effective.

- An efficient way to secure large loads of items.

- Tough and durable.

- Suitable for heavy loads and rough handling.

- Easy to use.

- Does not require any specialised equipment.

Cons of using pallet wrap:

- May not provide enough protection for fragile or delicate items.

- Can be a hazard if it is not disposed of properly.

When to use pallet wrap

If you are looking for protective packaging that prevents damage during shipping or storage, pallet wrap is the right choice. Its strength is effective at keeping items in place and protecting the contents from dust, moisture, and other external elements. It can be used for shipping, transportation, warehouse storage, uniting loose items, and protecting products from the weather.

How to wrap a pallet

The goal of pallet wrapping is to keep the load stable, prevent damage during transit, and make it easier to handle. The key steps are as follows:- Check the pallet is clean and free of any sharp edges.

- Place your items on the pallet.

- Choose the right type of pallet wrap. It must be suitable for the weight and size of the load.

- Wrap around the base of the pallet and continue upwards, overlapping by at least 50%.

- When you reach the top, cut the wrap, secure the end with tape, and label the load.

Pallet wrap NZ

In conclusion, pallet wrap and shrink wrap are both versatile packaging solutions offering different benefits, depending on the type of items you need to package. While shrink wrap is ideal for smaller individual items, pallet wrap is designed to provide stability and protection for larger groups of items on a pallet.

At Primepac, we offer a range of pallet wrap solutions to meet the diverse needs of our customers, including stretch wrap, sustainable wrap, handheld grip wrap, and machine wrap.

Stretch wrap

Suitable for securely wrapping large loads, stretch film wrap is made of a flexible plastic material that can be stretched and tightened around the items being packaged. This provides a secure and snug fit, even for irregular shapes. Stretch pallet wrap is commonly used in various industries, including logistics, retail, and manufacturing. Popular product lines include the Easywrap range and the Ultiwrap range.

Sustainable wrap

For a more environmentally friendly option our sustainable wrap, Purewrap, is made from sustainably-grown sugar cane. It’s also 100% recyclable. As many businesses strive to reduce their environmental impact, the piles of plastic waste in your warehouse are a wise place to start and opting for a sustainable pallet wrap is the perfect first step.

Handheld grip wrap

If your team wraps pallets by hand, an ergonomic pallet wrap solution is a must. Our handheld grip wraps are easy to use and perfect for lightweight loads. We also recommend investing in a pallet wrap dispenser to streamline your packing operations.

Machine wrap

For a more efficient and consistent way to secure goods on pallets, consider opting for machine wrapping. The pallet wrapping machine applies stretch wrap evenly and tightly around the pallet, saving your staff time and energy. This is a cost-effective option for companies that wrap a high volume of pallets and is commonly used in logistics, retail, and manufacturing.

-2.png?width=200&height=200&name=Untitled%20design%20(1)-2.png)

At Primepac, we strive to keep your business running smoothly. That’s why we have a wide range of high-quality pallet wraps and accessories to streamline your packing operations. Our friendly team is always happy to provide expert advice, and our same-day dispatch means your team can keep up the good work without delay.

No matter what your packaging needs are, we have an effective solution for you. Contact us today for practical advice or browse our extensive range below.

.png)